420 Stainless Steel Pipe

Classification :

PRODUCT DETAILS

420 Stainless Steel Pipe Description

420 is a hardenable martensitic stainless steel that contains at least 12% chromium, just enough to provide corrosion resistance. It has good ductility in the annealed condition, but can be hardened to a minimum Rockwell hardness of 50 HRC, which is the highest hardness in the 12% chromium scale. Due to its hardening properties, 420 are not often welded, although this is possible. Martensitic stainless steel is designed for high hardness, and sometimes other properties will be affected to a certain extent. The corrosion resistance is lower than that of ordinary austenite grades, and its effective operating range is limited by its ductility loss at sub-zero temperatures and strength loss due to excessive tempering at high temperatures. The best corrosion resistance is obtained when the metal is hardened and subjected to surface grinding or polishing.

Product Parameters

|

Product Name |

420 Stainless Steel Pipe |

|

|

Type |

Steel Pipe |

|

|

Outer diameter |

Round Tube |

4mm-200mm |

|

Square Tube |

10*10mm-100*100mm |

|

|

Rectangular Tube |

10*20mm-50*100mm |

|

|

Wall Thickness |

0.6mm-6.0mm |

|

|

Length |

1-6 meters, Length can be customized |

|

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

|

Surface |

Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. |

|

|

Scope of Application |

Common applications for stainless steel pipes include food processing, Textile operations, Breweries, Water treatment plants, Oil and gas processing, Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. |

|

|

Certificate |

ISO, SGS, BV, etc. |

|

|

Production Technology |

Hot Rolling, Cold Rolling |

|

|

Edge Processing |

Edging, Trimming |

|

Chemical Composition

|

C |

Si |

Mn |

Cr |

S |

P |

|

≤ 0.15 |

≤1.0 |

≤1.0 |

12.0~14.0 |

≤ 0.03 |

≤ 0.04 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥634 |

≥440 |

≥20 |

Annealing≤ 223HB; quenching and tempering ≥ 192HB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.74 |

200 |

10.2 |

24.9 |

55 |

|

No |

China | Japan | USA | South Korea | Germany | India | Australia | Taiwan, China | |

|

|

GB |

JIS |

ASTM |

UNS |

KS |

DIN |

BIS |

AS |

CNS |

| Austenitic stainless steel | |||||||||

|

1 |

12Cr17Mn6Ni5N |

SUS201 |

201 |

S20100 |

STS201 |

1.4372 |

10Cr17Mn6Ni4N20 |

201-2 |

201 |

|

2 |

12Cr18Mn9Ni5N |

SUS202 |

202 |

S20200 |

STS202 |

1.4373 |

- |

- |

202 |

|

3 |

12Cr17Ni7 |

SUS301 |

301 |

S20200 |

STS301 |

1.4319 |

10Cr17Ni7 |

301 |

301 |

|

4 |

06Cr19Ni10 |

SUS304 |

304 |

S30400 |

STS304 |

1.4301 |

07Cr18Ni9 |

304 |

304 |

|

5 |

022Cr19Ni10 |

SUS304L |

304L |

S30403 |

STS304L |

1.4306 |

02Cr18Ni11 |

304L |

304L |

|

6 |

06Cr19Ni10N |

SUS304N1 |

304N |

S30451 |

STS304N1 |

1.4315 |

- |

304N1 |

304N1 |

|

7 |

06Cr19Ni9NbN |

SUS304N2 |

XM21 |

S30452 |

STS304N2 |

- |

- |

304N2 |

304N2 |

|

8 |

022Cr19Ni10N |

SUS304LN |

304LN |

S30453 |

STS304LN |

- |

- |

304LN |

304LN |

|

9 |

10Cr18Ni12 |

SUS305 |

305 |

S30500 |

STS305 |

1.4303 |

- |

305 |

305 |

|

10 |

06Cr23Ni13 |

SUS309S |

309S |

S30908 |

STS309S |

1.4833 |

- |

309S |

309S |

|

11 |

06Cr25Ni20 |

SUS310S |

310S |

S31008 |

STS310S |

1.4845 |

- |

310S |

310S |

|

12 |

06Cr17Ni12Mo2 |

SUS316 |

316 |

S31600 |

STS316 |

1.4401 |

04Cr17Ni12Mo2 |

316 |

316 |

|

13 |

06Cr17Ni12Mo2Ti |

SUS316Ti |

316Ti |

S31635 |

- |

1.4571 |

04Cr17Ni12MoTi20 |

316Ti |

316Ti |

|

14 |

022Cr17Ni12Mo2 |

SUS316L |

316L |

S31603 |

STS316L |

1.4404 |

~02Cr17Ni12Mo2 |

316L |

316L |

|

15 |

06Cr17Ni12Mo2N |

SUS316N |

316N |

S31651 |

STS316N |

- |

- |

316N |

316N |

|

16 |

022Cr17Ni13Mo2N |

SUS316LN |

316LN |

S31653 |

STS316LN |

1.4429 |

- |

316LN |

316LN |

|

17 |

06Cr18Ni12Mo2Cu2 |

SUS316J1 |

- |

- |

STS316J1 |

- |

- |

316J1 |

316J1 |

|

18 |

022Cr18Ni14Mo2Cu2 |

SUS316J1L |

- |

- |

STS316J1L |

- |

- |

- |

316J1L |

|

19 |

06Cr19Ni13Mo3 |

SUS317 |

317 |

S31700 |

STS317 |

- |

- |

317 |

317 |

|

20 |

022Cr19Ni13Mo3 |

SUS317L |

317L |

S31703 |

STS317L |

1.4438 |

- |

317L |

317L |

|

21 |

06Cr18Ni11Ti S |

SUS321 |

321 |

S32100 |

STS321 |

1.4541 |

04Cr18Ni10Ti20 |

321 |

321 |

|

22 |

06Cr18Ni11Nb |

SUS347 |

347 |

S34700 |

STS347 |

1.4550 |

04Cr18Ni10Nb40 |

347 |

347 |

| Duplex stainless steel | |||||||||

|

1 |

- |

SUS329J1 |

329 |

S32900 |

STS329J1 |

1.4477 |

- |

329J1 |

- |

|

2 |

022Cr23Ni5Mo3N |

- |

S32205 |

F60 |

- |

1.4462 |

- |

2205 |

2205 |

|

3 |

022Cr25Ni7Mo4N |

- |

S32750 |

F53 |

- |

1.4410 |

- |

2507 |

2507 |

| Ferritic stainless steel | |||||||||

|

1 |

06Crl3Al |

SUS405 |

405 |

S40500 |

STS405 |

1.4002 |

04Cr13 |

405 |

405 |

|

2 |

022Cr11Ti |

SUH409 |

409 |

S40900 |

STS409 |

1.4512 |

- |

409L |

409L |

|

3 |

022Cr12 |

SUS410L |

- |

- |

STS410L |

- |

- |

410L |

410L |

|

4 |

10Cr17 |

SUS430 |

430 |

S43000 |

STS430 |

1.4016 |

05Cr17 |

430 |

430 |

|

5 |

10Cr17Mo |

SUS434 |

434 |

S43400 |

STS434 |

1.4113 |

- |

434 |

434 |

|

6 |

022Cr18NbTi |

- |

- |

S43940 |

- |

1.4509 |

- |

439 |

439 |

|

7 |

019Cr19Mo2NbTi |

SUS444 |

444 |

S44400 |

STS444 |

1.4521 |

- |

444 |

444 |

| Martensitic stainless steel | |||||||||

|

1 |

12Cr12 |

SUS403 |

403 |

S40300 |

STS403 |

- |

- |

403 |

403 |

|

2 |

12Cr13 |

SUS410 |

410 |

S41000 |

STS410 |

1.4006 |

12Cr13 |

410 |

410 |

|

3 |

20Cr13 |

SUS420J1 |

410 |

S42000 |

STS420J1 |

1.4021 |

20Cr13 |

420 |

420J1 |

|

4 |

30Cr13 |

SUS420J2 |

- |

- |

STS420J2 |

1.4028 |

30 Cr13 |

420J2 |

420J2 |

|

5 |

68Cr17 |

SUS440A |

440A |

S44002 |

STS440A |

- |

- |

440A |

440A |

Packing and delivery

We have been committed to becoming a well-known one-stop steel supplier. So far, our products have been exported to more than 100 countries and regions, including Turkey, Russia, Saudi Arabia, UAE, Iran, Kuwait, Poland, Philippines, Indonesia, Kazakhstan, Brazil, Mexico, Egypt, Nigeria, South Africa, Australia, etc.

CLIENT FEEDBACK

Whether it is steel export or import, it can ensure efficient transactions, timely supply, and fast delivery to meet customer needs.Our adheres to the business philosophy of "quality first, customer first, honest cooperation, and common development" and is committed to providing customers with high-quality products and services.

CUSTOMER VISIT

We focus on technological innovation and management optimization, and continuously improve our competitiveness to adapt to market changes and customer expectations.

Customer Visit

Customer Visit

Customer Visit

PARTNER

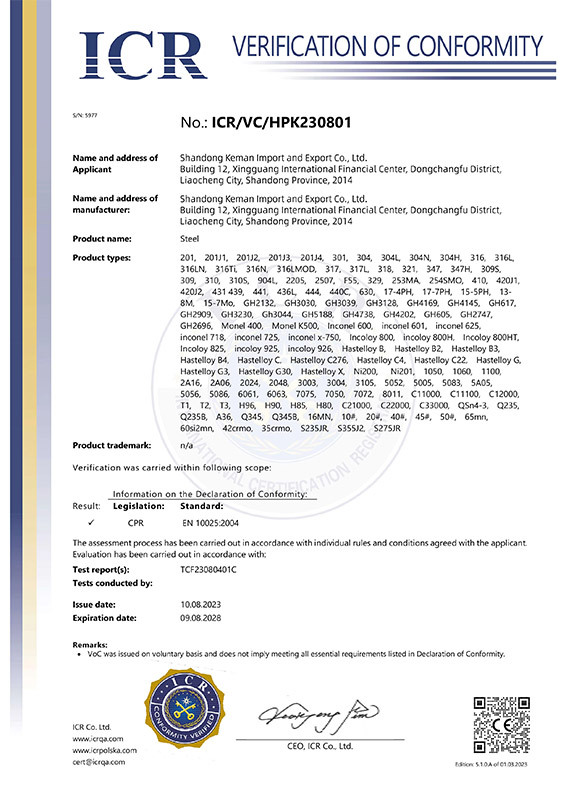

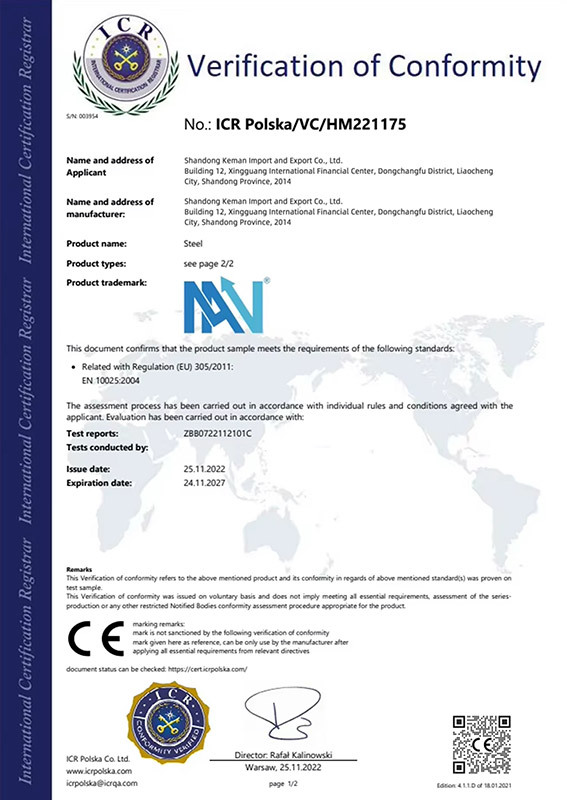

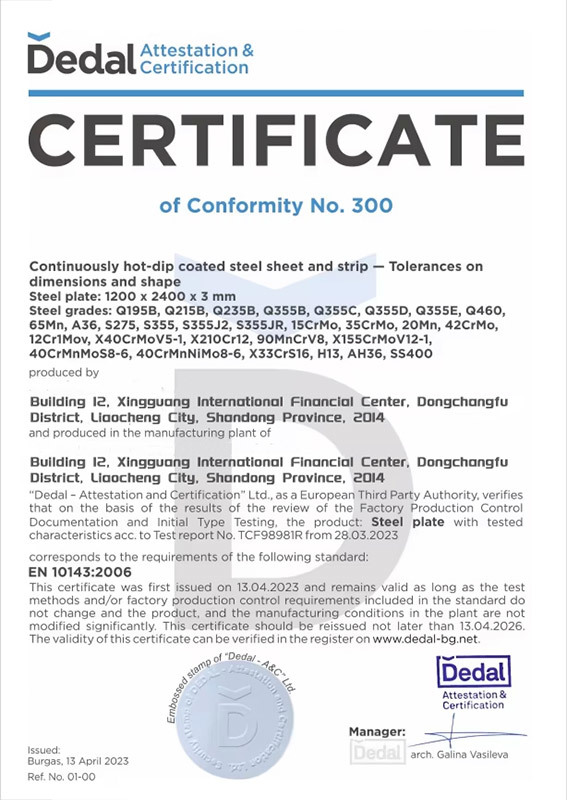

CERTIFICATIONS

Honor

Honor

Honor

Honor

Honor

Honor

APPLICATION AREAS

Ship

Chemical Industry

Electricity

Oil and gas transportation

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE