Inconel 601 / N06601 / 2.4851

Classification :

PRODUCT DETAILS

Inconel 601 rod / Inconel 601 sheet /Inconel 601 pipe / Inconel 601 plate / Inconel 601 coil

| Alloy grade | % | Ni | Cr | Fe | C | Mn | Si | Cu | Al | P | s |

| Inconel 601 | MIN | 58 | 21 | 1.0 | |||||||

| MAX | 63 | 25 | Balance | 0.1 | 0.5 | 0.5 | 1 | 1.7 | 0.02 | 0.015 |

| Density | 8.1g/cm3 |

| Melting Point | 1320-1370℃ |

| Alloys and Conditions | Tensile strength Rm N/mm2 | Yield strength RP0.2N/mm2 | Elongation A5% | Brinell hardness HB |

| Annealing treatment | 650 | 300 | 30 | - |

| Solution treatment | 600 | 240 | 30 | ≤220 |

Inconel 601 has the following features:

1. Excellent oxidation resistance at high temperatures

2. Excellent carbonation resistance

3. Good resistance to oxidation in sulfur-containing atmospheres

4. It has good mechanical properties at both room temperature and high temperature.

5. Excellent resistance to stress corrosion cracking. Due to the control of carbon content and grain size, 601 has high creep rupture strength, so it is recommended to use 601 in areas above 500°C.

Inconel 601 metallographic structure:

601 is a face-centered cubic lattice structure.

Inconel 601 Corrosion Resistance:

An important property of 601 alloy is its oxidation resistance at temperatures up to 1180°C. Even under very harsh conditions, such as during heating and cooling cycles, 601 can form a dense oxide film and achieve high peeling resistance. 601 has good carbonation resistance. Due to its high chromium and aluminum content, 601 has good oxidation resistance in high-temperature sulfur-containing atmospheres.

Inconel 601 application areas:

1. Trays, baskets and fixtures used in heat treatment factories.

2. Wire strand annealing and radiant tubes, high speed gas burners, wire mesh belts in industrial furnaces.

3. Isolation tanks in ammonia reforming and catalytic support grids in nitric acid manufacturing.

4. Exhaust system components

5. Combustion chamber of solid waste incinerator

6. Pipe supports and soot disposal components

7. Exhaust gas detoxification system components

8.Oxygen reheater

CLIENT FEEDBACK

Whether it is steel export or import, it can ensure efficient transactions, timely supply, and fast delivery to meet customer needs.Our adheres to the business philosophy of "quality first, customer first, honest cooperation, and common development" and is committed to providing customers with high-quality products and services.

CUSTOMER VISIT

We focus on technological innovation and management optimization, and continuously improve our competitiveness to adapt to market changes and customer expectations.

Customer Visit

Customer Visit

Customer Visit

PARTNER

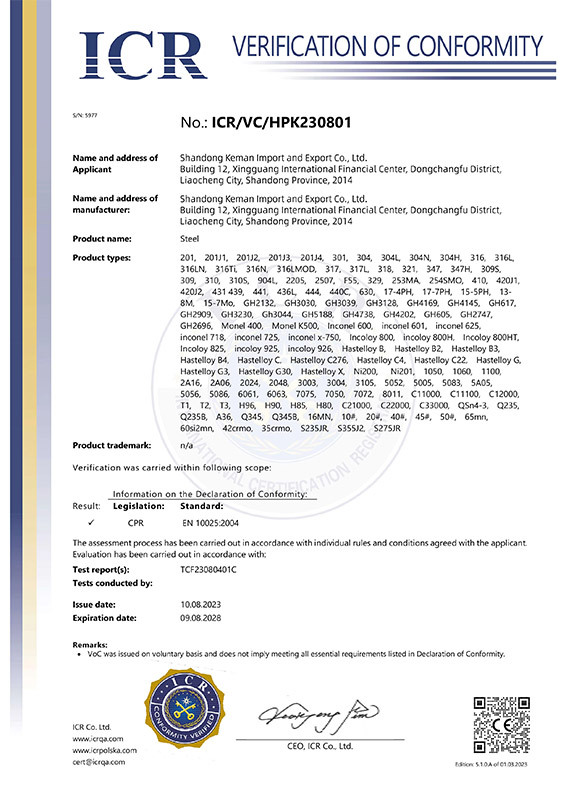

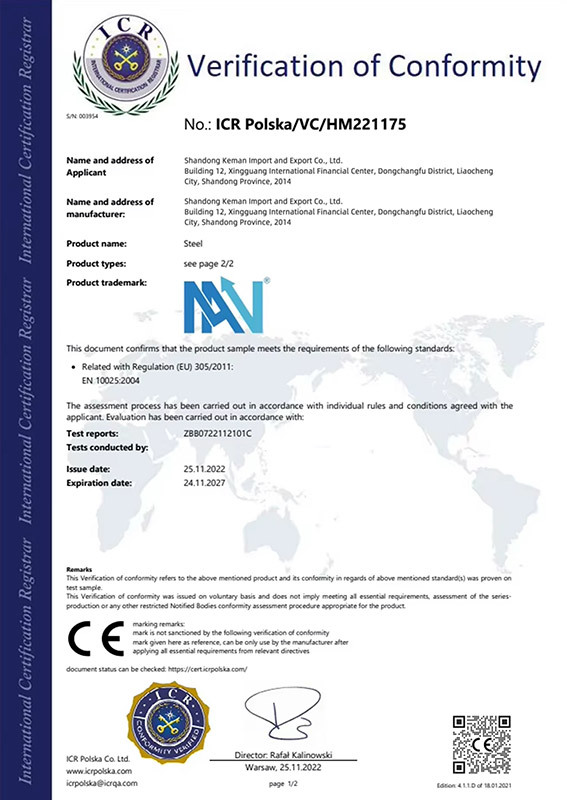

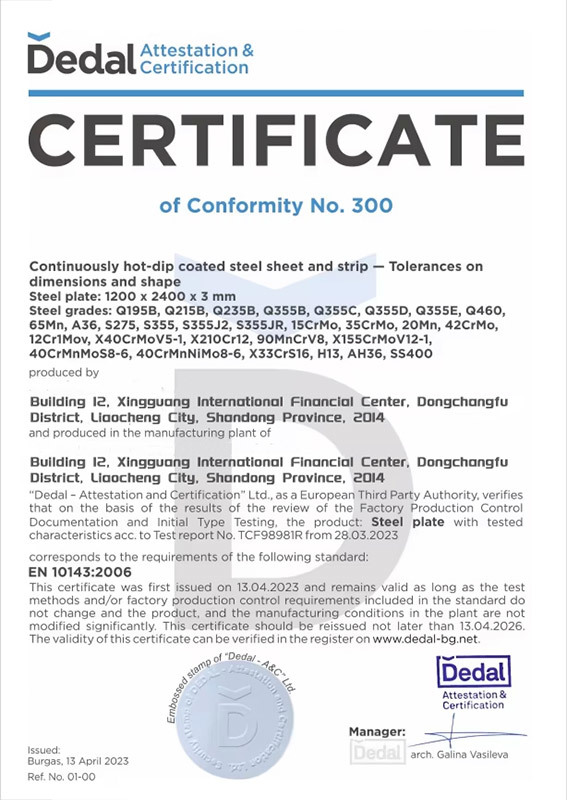

CERTIFICATIONS

Honor

Honor

Honor

Honor

Honor

Honor

APPLICATION AREAS

Ship

Chemical Industry

Electricity

Oil and gas transportation

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE