INCOLOY A-286

Classification :

PRODUCT DETAILS

Incoloy A-286 Similar grades of Incoloy A-286 A286, UNSS66286 (USA), ZbNCT25 (France), P.Q.A286 (USA)It is suitable for manufacturing high-temperature load-bearing parts of aircraft engines that work for a long time below 650℃, such as turbine disks, press disks, rotor blades and fasteners. The alloy can produce deformed products of various shapes, such as disks, forgings, plates, rods, wires and rings

1.4 Chemical composition of Incoloy A-286 :

|

Cr |

Ni |

Mo |

Ti |

Fe |

V |

B |

Mn |

Al |

Si |

P |

S |

|

|

≤ |

||||||||||||

|

≤0.08 |

13.5~16.0 |

24.0~27.0 |

1.00~1.50 |

1.75~2.30 |

margin |

0.10~0.50 |

0.001~0.010 |

1.00~2.00 |

0.04 |

1.00 |

0.030 |

0.020 |

Note: 1 The standard for cold-drawn bars, round cakes and ring blanks is ω(Ti)1.80%~2.35%.

2 The standard for hot-rolled and cold-rolled plates is ω(B)0.003%~0.010%, ω(Mn)≤2.00%, ω(P)≤0.020%, ω(S)≤0.015%.

3 The standard for cold-drawn welding wire is ω(Al)≤0.35%, ω(Ti)1.75%~2.35%, ω(Si)0.40%~1.00%, ω(P)≤0.020%, ω(S)≤0.015%.

4 The standard for wire for cold heading is ω(Ti)1.75%~2.35%, ω(Si)0.40%~1.00%, ω(P)≤0.025%, ω(S)≤0.020%.

5 Hot-rolled and forged bar standards

1.5 Incoloy A-286 heat treatment system The Incoloy A-286 heat treatment system specified in the material standard is shown in Table 1-3; the heat treatment system for high-quality Incoloy A-286 is 900℃±10℃, 1~2h, oil cooling + 750℃±10℃, 16h, air cooling. Note: Before determining the analysis method, the trace elements Se, Te, and Tl are reported as measured data and are not used as the basis for acceptance.

Note: According to the standards for cold-drawn bars and cold-drawn wires, if the performance test fails, it can be aged at no more than 760℃ for 16h, and delivery will be made after passing the test.

| Material Variety | Heat treatment system |

| Bars, round cakes |

980~1000℃,1~2h,Oil cooler+700~720℃,12~16h,Air Cooling |

| Hot rolled plate, cold rolled plate |

980~1000℃,Air Cooling+700~720℃,12~16h,Air Cooling |

| Cold drawn rod |

980~1000℃,1~2h,Oil cooler+700~720℃,16h,Air Cooling |

| Ring blank |

980~990℃,1~2h,Oil cooler+700~720℃,16h,Air Cooling |

| Cold drawn wire for cold heading |

980~1000℃,Water Cooling OT Oil cooler+700~720℃,16h,Air Cooling

|

CLIENT FEEDBACK

Whether it is steel export or import, it can ensure efficient transactions, timely supply, and fast delivery to meet customer needs.Our adheres to the business philosophy of "quality first, customer first, honest cooperation, and common development" and is committed to providing customers with high-quality products and services.

CUSTOMER VISIT

We focus on technological innovation and management optimization, and continuously improve our competitiveness to adapt to market changes and customer expectations.

Customer Visit

Customer Visit

Customer Visit

PARTNER

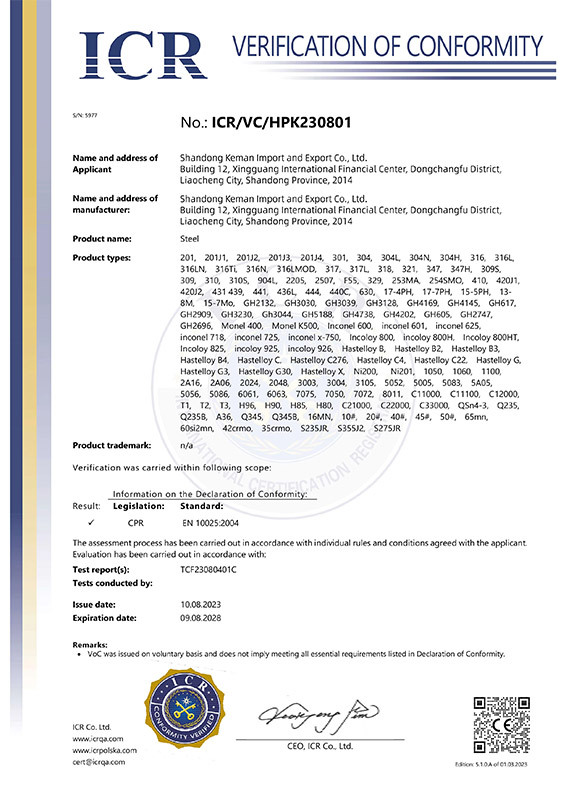

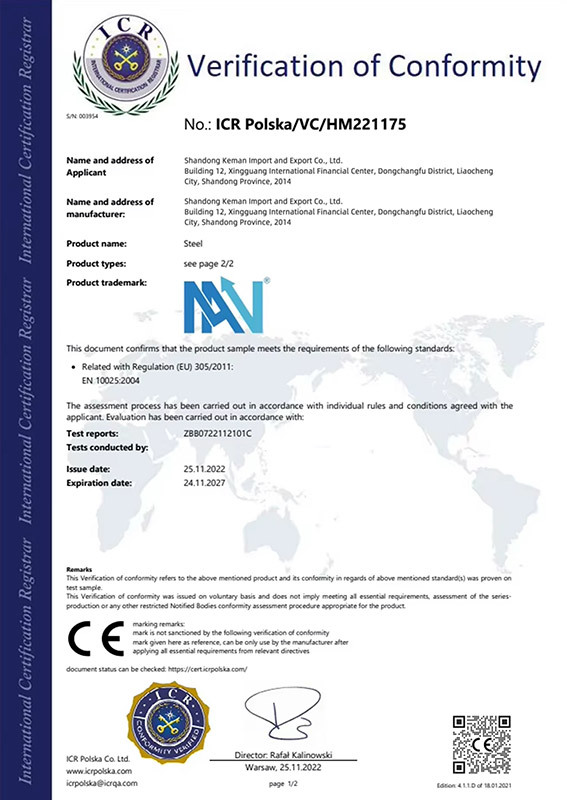

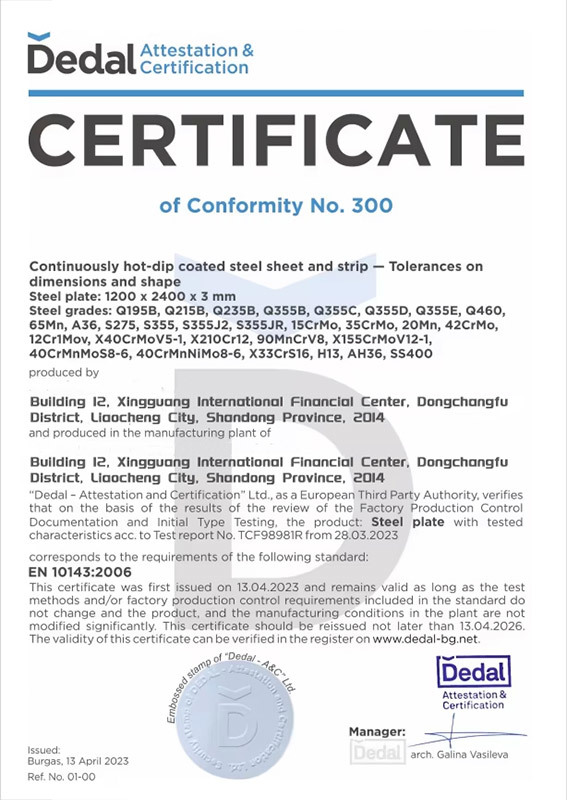

CERTIFICATIONS

Honor

Honor

Honor

Honor

Honor

Honor

APPLICATION AREAS

Ship

Chemical Industry

Electricity

Oil and gas transportation

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE