INCOLOY825 / N08825

Classification :

PRODUCT DETAILS

一、Similar grades of Incoloy825:

NS142 (China), NC21FeDu (France), W.Nr.2.4858 NiCr21Mo (Germany) NA16 (UK)

二、Chemical composition of Incoloy825:

| Alloy grade | % | Ni | Cr | Fe | Mo | Nb | Co | C | Mn | Si | S | Cu | Al | Ti |

| Incoloy 825 | min | 38.0 | 19.5 | margin | 2.5 | 1.5 | 0.6 | |||||||

| max | 46.0 | 23.5 | 3.5 | 0.025 | 1.0 | 0.5 | 0.01 | 3.0 | 0.2 | 1.2 |

Incoloy825 production implementation standards:

Incoloy825 metallographic structure:

The alloy has a stable face-centered cubic structure. Chemical composition and proper heat treatment ensure that corrosion resistance is not weakened by sensitization.

三、Incoloy825 process performance and requirements:

1. If the alloy heating environment contains sulfur, phosphorus, lead or other low-melting-point metals, Nicrofer 6023/6023H alloy will become brittle. Impurities come from paint, chalk, lubricating oil, water, fuel, etc. for marking. The sulfur content of the fuel should be low, such as the impurity content of liquefied gas and natural gas should be less than 0.1%, the sulfur content of city gas should be less than 0.25g/m3, and the sulfur content of petroleum gas should be less than 0.5%.

2. The suitable hot working temperature of the alloy is 1150-900℃, and the cooling method can be water quenching or rapid air cooling.

3. Use tungsten electrode inert gas shielded welding, plasma arc welding, manual sub-arc welding, metal inert gas shielded welding, and melt inert gas shielded welding, among which pulse arc welding is an option.

四、Specifications and Availability :We can supply various specifications of plates, bars, forgings, strips, wires, round cakes, ring blanks and ring forgings.

CLIENT FEEDBACK

Whether it is steel export or import, it can ensure efficient transactions, timely supply, and fast delivery to meet customer needs.Our adheres to the business philosophy of "quality first, customer first, honest cooperation, and common development" and is committed to providing customers with high-quality products and services.

CUSTOMER VISIT

We focus on technological innovation and management optimization, and continuously improve our competitiveness to adapt to market changes and customer expectations.

Customer Visit

Customer Visit

Customer Visit

PARTNER

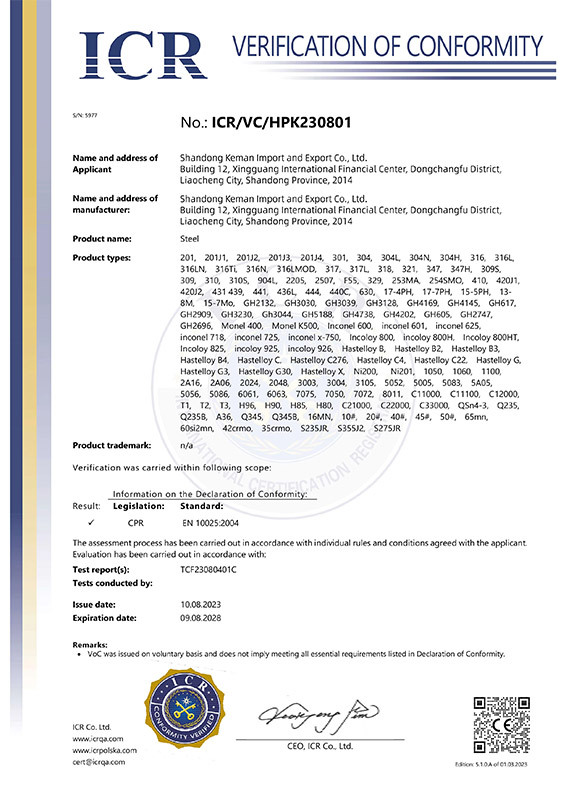

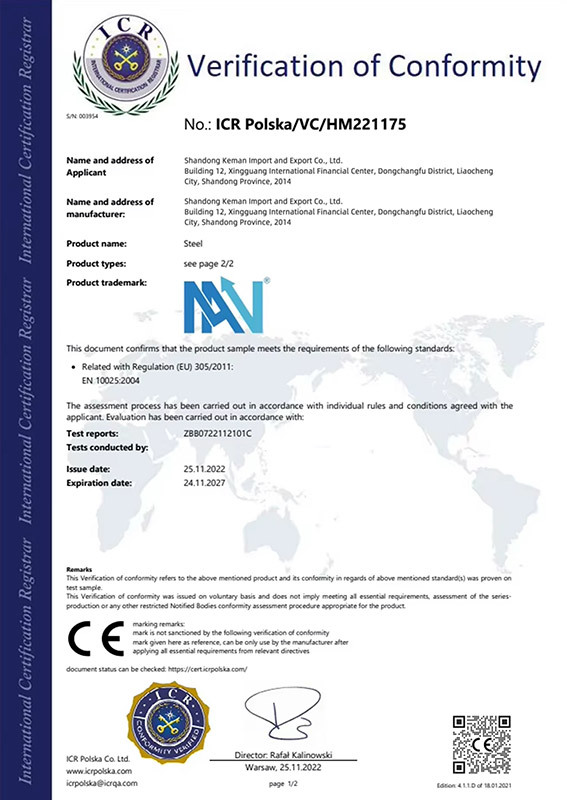

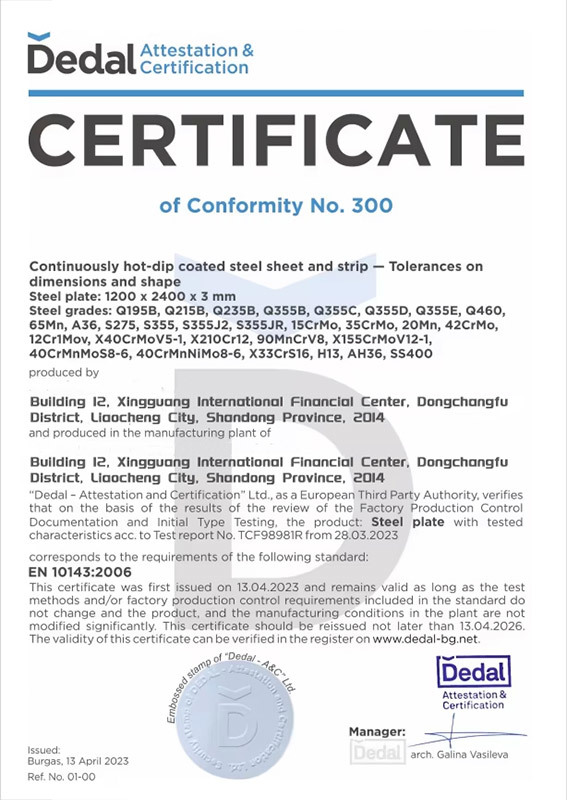

CERTIFICATIONS

Honor

Honor

Honor

Honor

Honor

Honor

APPLICATION AREAS

Ship

Chemical Industry

Electricity

Oil and gas transportation

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE