5083 Aluminum Plate

Classification :

PRODUCT DETAILS

5083 Aluminum Plate Description

5083 aluminum is a non-heat-treatable alloy known for its resistance to extreme environments, including seawater corrosion and industrial chemicals. Although Al-5083 has limited machinability due to its strength, it is a material for marine and aquatic applications and is commonly used in the shipbuilding industry. Other uses for this alloy include transportation applications such as railroads, trucks, and car bodies, as well as pressure vessels and food processors.

Product Parameters

|

Width |

20-3000mm or Customized |

Thickness |

0.1-120mm or Customized |

|

Length |

100-12000mm or Customized |

Certificate |

ISO, SGS, BV |

|

Standard |

JIS, AISI, ASTM, GB, DIN, EN, etc. |

||

|

Brand |

1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5754, 5A05, etc. 6000 Series: 6061, 6063, 6082, 6A02, etc. 7000 Series: 7050, 7475, 7075, etc. 8000 Series: 8A06, 8011, 8090, etc. |

||

|

Surface |

Coating, Embossing, Drawing, Polishing, Anodizing, etc. |

||

|

OEM Service |

Punching, Cutting Special Size, Making Flat Surface, Surface Treatment, etc. |

||

|

Delivery Time |

Received 30%, After deposit 7-15 working day |

||

|

Application |

Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware And Other Fields, etc. |

||

|

Sample |

Free Offers Sample |

||

|

Packaging |

Strapping, plastic bag, film, wooden pallet Standard seaworthy export packing or according to customer requirement |

||

Chemical Composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: Each |

Others: Total |

Al: Min. |

|

1050 |

0.25 |

0.40 |

0.05 |

0.05 |

0.05 |

- |

0.05 |

0.03 |

0.03 |

- |

99.50 |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

0.05 |

0.03 |

0.03 |

- |

99.60 |

|

1070 |

0.20 |

0.25 |

0.04 |

0.03 |

0.03 |

- |

0.04 |

0.03 |

0.05 |

- |

99.70 |

|

1100 |

0.95 Si Fee |

0.05~0.20 |

0.05 |

- |

- |

0.1 |

- |

0.05 |

0.15 |

99.0 |

|

|

2014 |

0.5~1.2 |

0.7 |

3.9~5.0 |

0.4~1.2 |

0.2~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Margin |

|

2017 |

0.2~0.8 |

0.7 |

3.5~4.5 |

0.4~1.0 |

0.4~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

91.5 - 95.5 |

|

2024 |

0.50 |

0.50 |

3.8~4.9 |

0.3~0.9 |

1.2~1.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Margin |

|

3003 |

0.60 |

0.70 |

0.05~0.20 |

1.0~1.5 |

- |

- |

0.10 |

- |

0.05 |

0.15 |

Margin |

|

3A21 |

0.60 |

0.70 |

0.20 |

1.0-1.6 |

0.05 |

- |

0.15 |

0.1-0.2 |

- |

- |

Margin |

|

3004 |

0.30 |

0.70 |

0.25 |

1.0~1.5 |

0.8~1.3 |

- |

0.25 |

- |

0.05 |

0.15 |

Margin |

|

3005 |

0.60 |

0.70 |

0.30 |

1.0~1.5 |

0.2~0.6 |

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

Margin |

|

3105 |

0.60 |

0.70 |

0.30 |

0.3~0.8 |

0.2~0.8 |

0.20 |

0.40 |

0.10 |

0.05 |

0.15 |

Margin |

|

5005 |

0.30 |

0.70 |

0.20 |

0.20 |

0.5~1.1 |

0.1 |

0.25 |

- |

0.05 |

0.15 |

Margin |

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

2.2~2.8 |

0.15~0.35 |

0.10 |

- |

0.05 |

0.15 |

Margin |

|

5754 |

0.40 |

0.40 |

0.10 |

0.50 |

2.6~3.6 |

0.30 |

0.20 |

0.15 |

0.05 |

0.15 |

Margin |

|

5A05 |

0.50 |

0.50 |

0.10 |

0.3-0.6 |

4.8-5.5 |

- |

0.20 |

- |

0.05 |

0.05 |

Margin |

|

5083 |

0.40 |

0.40 |

0.10 |

0.4~1.0 |

4.0~4.9 |

0.05~0.25 |

0.25 |

0.15 |

0.05 |

0.15 |

Margin |

|

6061 |

0.40~0.8 |

0.70 |

0.15~0.4 |

0.15 |

0.8~1.2 |

0.04~0.35 |

0.25 |

0.15 |

0.05 |

0.15 |

Margin |

|

6082 |

0.70~1.3 |

0.50 |

0.10 |

0.4~1.0 |

0.6~1.2 |

0.25 |

0.20 |

0.10 |

0.05 |

0.15 |

Margin |

|

7075 |

0.40 |

0.50 |

1.2~2.0 |

0.30 |

2.1~2.9 |

0.18~0.28 |

5.1~6.1 |

0.20 |

0.05 |

0.15 |

Margin |

Mechanical Properties

|

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation Rate (%) |

Hardness (HV) |

|

290 |

145 |

22 |

87 |

Physical Performance

|

Density |

Melting Point |

Modulus of Elasticity |

Thermal Conductivity |

|

2.65 Kg/m³ |

591-638 °C |

70.3GPa |

117W/m.K |

Annealing State

|

Brand |

Annealing State |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Scope of Application

|

Aluminum Uses And Application Area |

|

|

Food Packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Building |

Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

|

Transportation |

Auto parts, passenger car bodies, aviation ships and air cargo containers. |

|

Electronic Equipment |

Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

|

Consumer Goods |

Umbrellas, cooking utensils, sports equipment, etc |

|

Other |

Military, color coated aluminum plate |

| Alloy Series | Chinese standard | American standard | European standard |

|

1xxx series |

1050 |

- |

- |

|

1050A |

- |

EN AW-1050A |

|

|

1060 |

1060 |

- |

|

|

1100 |

1100 |

- |

|

|

2xxx series |

2024 |

2024 |

EN AW-2024 |

|

3xxx series |

3003 |

3003 |

EN AW-3003 |

|

3004 |

3004 |

EN AW-3004 |

|

|

3005 |

3005 |

EN AW-3005 |

|

|

3105 |

3105 |

EN AW-3105 |

|

|

5xxx series |

5005 |

5005 |

EN AW-5005 |

|

5052 |

5052 |

EN AW-5052 |

|

|

5754 |

5754 |

EN AW-5754 |

|

|

5083 |

5083 |

EN AW-5083 |

|

|

5086 |

5086 |

EN AW-5086 |

|

|

5182 |

- |

EN AW-5182 |

|

|

5049 |

- |

EN AW-5049 |

|

|

5251 |

- |

EN AW-5251 |

|

|

6xxx series |

6061 |

6061 |

EN AW-6061 |

|

6082 |

- |

EN AW-6082 |

|

|

7xxx series |

7075 |

7075 |

EN AW-7075 |

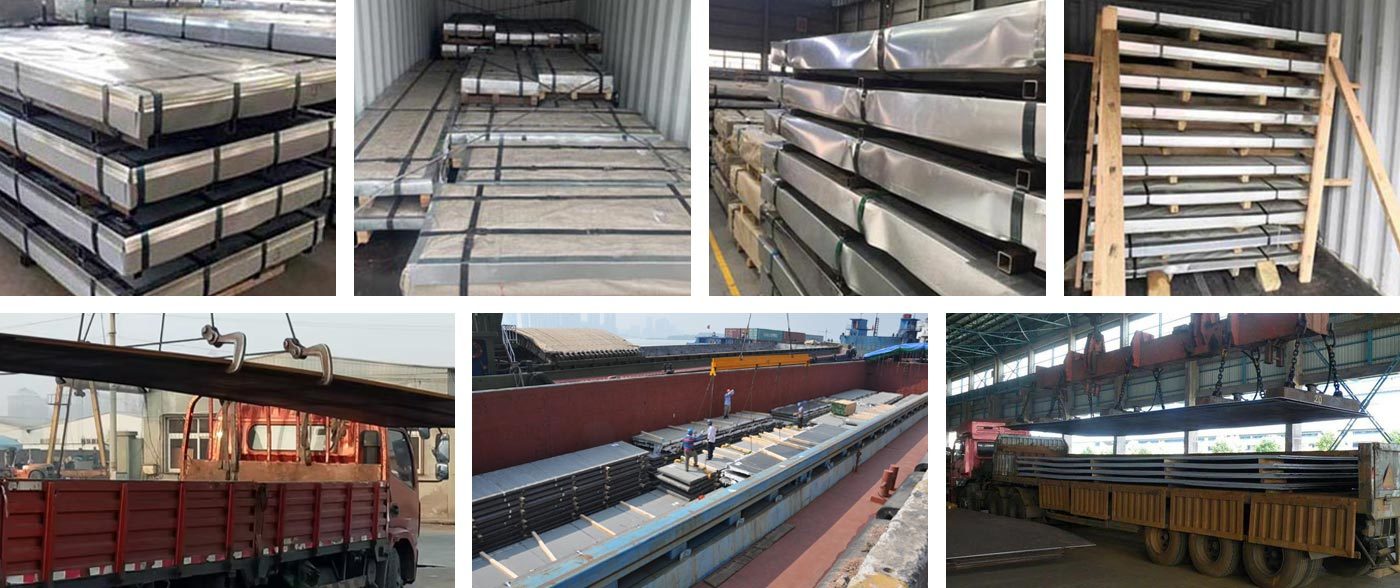

Packing and delivery

We have been committed to becoming a well-known one-stop steel supplier. So far, our products have been exported to more than 100 countries and regions, including Turkey, Russia, Saudi Arabia, UAE, Iran, Kuwait, Poland, Philippines, Indonesia, Kazakhstan, Brazil, Mexico, Egypt, Nigeria, South Africa, Australia, etc.

CLIENT FEEDBACK

Whether it is steel export or import, it can ensure efficient transactions, timely supply, and fast delivery to meet customer needs.Our adheres to the business philosophy of "quality first, customer first, honest cooperation, and common development" and is committed to providing customers with high-quality products and services.

CUSTOMER VISIT

We focus on technological innovation and management optimization, and continuously improve our competitiveness to adapt to market changes and customer expectations.

Customer Visit

Customer Visit

Customer Visit

PARTNER

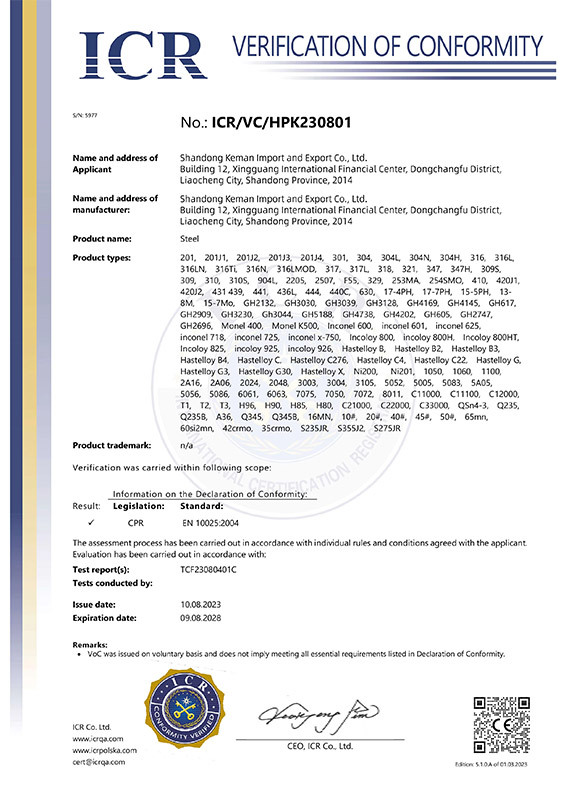

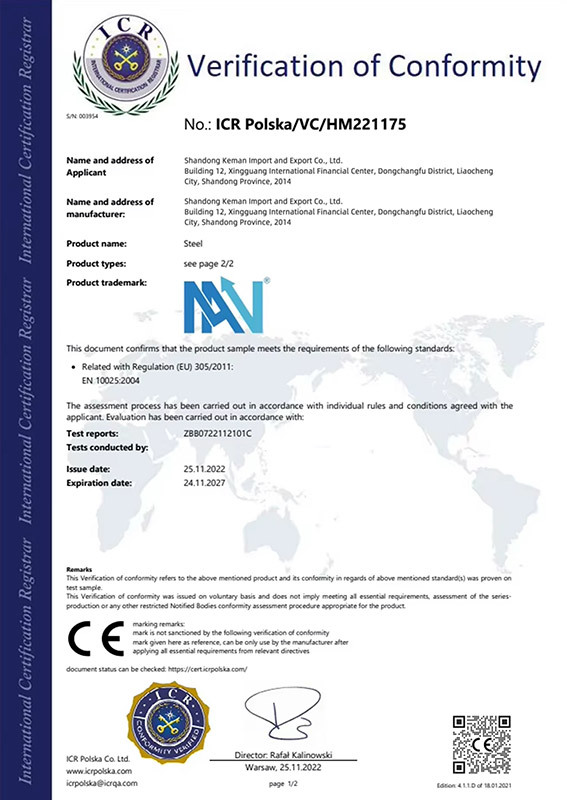

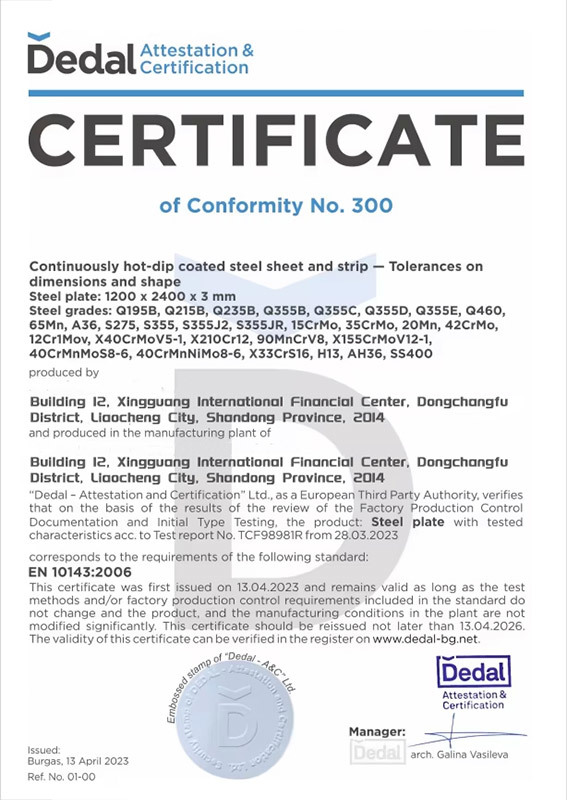

CERTIFICATIONS

Honor

Honor

Honor

Honor

Honor

Honor

APPLICATION AREAS

Ship

Chemical Industry

Electricity

Oil and gas transportation

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE